Competitive Advantage through Efficiency

Get Assignment Answers on Aldi Lean Production – Competitive Advantage through Efficiency. AssignmentHelpAUS.com.com has a huge network of customers across the globe, especially from Australia. Our customer base mainly comprises college and university students who avail the of online assignment help in various academic subjects.

Words: 1200

Introduction

The food retail industry is a highly competitive market. More so than ever, organisations need to offer customers value for money. Customers want the best quality products at the lowest possible prices. With such tough competition it is vital for organisations to understand what their customers want. Aldi understands that its customers want value for money but do not want to compromise on quality. This case study will demonstrate how Aldi uses a lean approach to its business operations to offer its customers quality products at competitive prices.

Since opening its first store in 1913, Aldi has established itself as a reputable retailer operating in international markets including Germany, Australia and the U.S. Aldi has over 7,000 stores worldwide. What distinguishes Aldi from its competitors is its competitive pricing strategy without reducing the quality of its products. In fact, in some cases Aldi’s products are 30% cheaper than those offered by its competitors. Aldi can do this because the business operates so efficiently. Efficiency is the relationship between inputs and corresponding outputs. For Aldi operating efficiently involves reducing costs in all areas of the business.

Some of the key areas where Aldi is able to minimise costs are by saving time, space, effort and energy. Aldi’s approach to doing this is to run its business around the principles of lean thinking.

Aldi has a no-nonsense approach to running its business. Whereas other food retailers have elaborate displays, additional services and promotions that draw customers into the business, Aldi’s core purpose is to ‘provide value and quality to our customers by being fair and efficient in all we do’. Everything Aldi does is focused around giving its customers value for money.

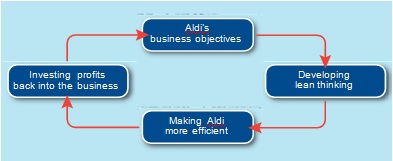

Through being efficient and cutting costs Aldi can then invest profits back into the business. They can then be used to further meet its business objectives for growth. Efficiency is not something that is achieved overnight. Lean thinking is a continuous process that constantly enables Aldi to improve the way in which it meets its business objectives. This enables Aldi to develop an ambitious investment programme to develop new properties and suppliers as well as to provide benefits for employees.

Lean production

Lean production is quite simply about getting more from less. The aim of lean production is to reduce the quantity of resources used in providing goods and services for consumers. At the same time, it is about making the organisation more efficient. Lean production involves eliminating waste and therefore using less labour, materials, space and time. This in turn reduces costs.

However, for Aldi, lean production is not just about reducing costs for the business, it is also about passing these savings on to its customers to offer value for money.

Lean production is based on a number of efficiency concepts, such as:

- Continuous improvement – a culture whereby all employees are constantly involved in making improvements to quality

- Just-in-time production – materials are received just as they are needed, eliminating the need to maintain large stock levels

- Time based management – an approach that aims to reduce the time wasted in business This usually requires a multi-skilled and flexible workforce.

- Total quality management (TQM) – a quality assurance ideal where all workers have a responsibility for getting it ‘right first time’

Although lean production is often considered in terms of manufacturing, these principles can equally be applied to service organisations. The principles of lean production are planned and built into everything that Aldi does. This starts within its supply chain. For example, up to 60% of Aldi’s fruit and vegetables are sourced locally where possible, reducing the need for long and costly delivery journeys. This demonstrates a time based management approach. The principles of time based management are also built into the training provided for Aldi’s employees. Training enables Aldi to eliminate waste and cut costs. Through training staff to do a variety of tasks around store Aldi can minimise its staff requirements. This method results in staff gaining knowledge of the whole business, as such they are able to offer a much higher level of customer service. Staff costs can also be reduced as fewer staff are required if they can perform a variety of duties throughout the store.

Aldi also applies this time based management approach to its product range. For example, Aldi sells fewer variations of each product. In contrast competitors may sell a larger variety of different brands, sizes and packaging. By selling fewer varieties of each product Aldi can buy much larger quantities. This enables it to take advantage of economies of scale and source products more cost effectively. This in turn means that Aldi needs less space to display its products. As a result Aldi’s stores can be smaller.

The three core values of Aldi are simplicity, consistency and responsibility. Lean production ties in closely with these values. For example, Aldi stores are simple in design and all stores are very similar which creates consistency. Responsibility is an important aspect of all areas of the business, from training and developing employees to drive the business forward as part of continuous improvement, to taking an active role in its supply chain to ensure continuous improvement. Such actions have helped it to develop an international influence in different markets.

For REF… Use: #getanswers2001893