Accounting Case Study Assignment – Baklava Done Better LLC

Stuck with your Baklava Done Better LLC Case Study Assignment? AssignmentHelpAUS is a highly acknowledged Homework Help provider among the students in Australia. We offer our Assignment Writing Help on more than 100 subjects with the help of our highly knowledgeable and well-trained writers. In order to get the best writing service on Case Study, Essay Writing, etc., students should place an order at our site.

Assignment Details:-

- Document Type :: Assignment help (any type)

- Subject :: Accounting

- Deadline :*: As Per Required

- Number of Words :: 3500

- Citation/Referencing Style :: APA

Case Study Assignment

Baklava Done Better LLC (BDB) is a supplier of agave-based syrup to producers and retailers of Middle Eastern sweets including: Baklava, Maamoul, Deblah, and Makroud. BDB was incorporated in Dubai in 2013 by five members of the Kachab family whom all became shareholders. The business operated by importing raw agave that was then manufactured into three types of syrups: Agave Syrup (AG), Agave-Lite Syrup (AGL) and Agave Super-Lite Syrup (AGSL). After five years of success, BDB faced a major disruption in the supply of its key ingredient raw agave (RAG).During the first quarter of 2018, BDB will be unable to procure the amount of syrups they need to meet forecasted demand for their three products. BDB now needs to decide how to best balance its production to maximize its profits& keep their customers intact.

Product Innovation History

BDB was founded on the belief that there was an opportunity to introduce the popular “natural” and “organic” trend to the Middle Eastern sweets category. After several iterations of consumer tasting samples and perfecting their formula, BDB launched agave-based syrup as a substitute for traditional refined-sugar-cane syrup. For the first two years, Agave Syrup (AGS) was the only product they manufactured.

AG has more calories than traditional refined-sugar-cane syrup. However, clients of BDB reported that Agave Syrup had increased the shelf life of their sweets, which in turn decreased losses on expired product. BDB’s clients were happy with the Agave Syrup innovation but wanted a product that was lower in calories. After several months of trials, BDB was able to refine the raw agave in a different way which reduced the number of calories in the product. In 2015, Agave-Lite-Syrup (AGL) was introduced and Agave-Super-Lite-Syrup (AGSL) was added the following year. DBD buys raw agave in larger containers and sell the different syrup products in containers of 20 kg each.

The lighter versions of the products were more expensive, hence not all existing BDB clients adopted them. However, other customers who were at first reluctant to adopt a higher calorie Agave started buying Agave-Lite and Agave-Super-Lite syrups. Overall, both lighter versions were an overwhelming success and BDB had enough production capacity to meet the demand for all products.

The Kachab family members were happy introducing an innovative product in what many would consider a traditional niche. All products were doing well, serving different segments and consumers tastes. There was virtually no overlap in the products due to their different tastes, calories and selling prices. In fact, when each new product was launched, there was no cannibalization of sales of the previously existing products.

Furthermore, because of the longer shelf life, Baklava producers were now selling their sweets outside of the Middle East.

The Kachab Family

Bilal Kachab had the original idea of revolutionizing the baklava sweets industry. As a child, he would spend the summers at his grandmother’s house in Lebanon. Playing underneath the high table, he would catch and devour all the ingredients that spilled off the table while his grandmother handmade baklava sweets for her own shop. From those early memories, he knew that he wanted to be a part of the sweets business. Bilal quit his business development job in the energy industry in October 2012 to pursue his entrepreneurial dream by founding BDB.

Bilal was ready to put the required sweet equity into a start-up but lacked the funds to do so. He persuaded his aunt Sara and Sara’s husband to invest in the business. The couple was about to retire after having done significant savings and owning their own properties which they rented out. They both agreed to invest, provided that Bilal could produce a solid business plan. They also requested to be part of the management team involved in making strategic decisions. Furthermore, they also asked for their son Mahmoud Kachab – who had just graduated from a reputable Business School – to join the management team.

Bilal, now joined by Mahmoud, moved next to assess the baklava market. After talking with five of his childhood friends, Bilal learned that they had stop eating baklava long ago because of concerns of ingesting refined cane sugar. Bilal was prone to make rushed decisions. For him, this anecdotal evidence was enough to conclude that a substitute for cane sugar was the solution to revive the baklava industry.

Mahmoud on the other hand, wanted to do more thorough and extensive market research. Mahmoud was concerned that perhaps there were other reasons why baklava consumption was dropping. After several weeks of arguing, Mahmoud conducted a study and distributedsurveys to learn more about baklava consumers and producers.

While waiting for Mahmoud’s findings, Bilal reached out to his cousin Abyr Khaled. She was a biologist who spent years studying the multiple uses and properties of Agave in Mexico. Bilal commissioned Abyr to start formulating agave-based syrup using Bilal’s small kitchen in his one-bedroom apartment. After just two weeks, she found a recipe for an agave-based syrup that was well received among the extended Kachab family. They liked the taste. Bilal thought it was even better than his grandmother’s version!

While Mahmoud continued working on the market research, Bilal launched a quest to develop relationships with Middle Eastern baklava producers. Bilal had charisma when dealing with people. He was a very good listener and demonstrated genuine care for others. In a short time, Bilal had built strong relationships with most baklava producers in the region.

A few weeks later, Mahmoud concluded that the trend of organic and natural was growing among both consumers and non-consumers of baklava. His study predicted an increase in sales if baklava were to adopt the labels of “Organic” and “Natural”. Mahmoud’s study also favored agave as the main ingredient to support the claim of “organic and natural baklava.” Bilal said: “I knew it, you just waisted time and burned some of our savings doing that research.” Despite this comment, Mahmoud’s findings served as the input to prepare the business plan that would secure the funding from a untie Sara and husband.

By February 2013, Baklava Done Better LLC was incorporated in the Dubai Emirate with a capitalization of AED 3,000,000. The business flourished for four years. The income statement of the last quarter of 2017 is shown below:

| Income Statement for last quarter of 2017 | ||

| AED | ||

| Forecasted sales | 13,840,000.0 | |

| minus COGS | 11,056,000.0 | |

| Gross margin | 2,784,000.0 | |

| Admin expenses | 530,000.0 | |

| Shipping expenses | 465,300.0 | |

| Sales commission (3% of sales) | 415,200.0 | |

| Financial expenses | 44,000.0 | 1,454,500.0 |

| Net Profit | 1,329,500.0 | |

The number of units sold and sales volume of the three products were as follows:

| AG | AGL | AGSL | Total | |

| Actual sales (units) | 30,794 | 44,288 | 36,503 | 111,585 |

| Actual sales(AED) | 2,463,520.0 | 5,536,000.0 | 5,840,480.0 | 13,840,000.0 |

Family Compensation

Bilal – like any good salesperson – was aggressive and incentive oriented. To ensure that all family members would stay motivated and driving the business, Bilal persuaded the family to adopt a compensation scheme based on sales performance. Each family member was to receive a low salary, supplemented by an equal share of the total sales. The supplemental commission was set at 3% of sales price on every unit sold.

Since the company had grown successful quickly, there had been little analysis of production decisions. The Kachab family would make decisions of production based on gut feeling and giving preference for the highest price item. Doing so provided the highest possible sales commission for the family members.

Mahmoud, not wanting to waste his business education constantly sought opportunities to apply his learnings acquired during his Business studies. He opposed to the sales-based commission and preferred a profit-based incentive. He would refer to terms like “profit maximization,” “marginal analysis” and “product mix” which would be quickly disregarded by the Kachab family. The family always saw Mahmoud’s methods as unnecessary bureaucracy. After all, BDB had a steady growing cash flow without the need of overcomplicating their planning process.

Despite this, Mahmoud would always produce spreadsheets to forecast the next quarter. He wanted to be assured that the current set of decisions would always generate a higher forecasted profit vs. the year ago. So far, all planning decisions from the Kachab family had – luckily – resulted in higher profits forecast & actuals.

The Sourcing Issue

The main ingredient of the flagship products of BDB became raw agave which was imported from Mexico. Until recently raw agave was widely available, and it was a low-cost ingredient compared to the high price that the agave-based syrup was being sold to BDB’s clients. However, in December 2017, & due to a mud slide, the roads & bridges from the fields were destroyed and the supply of agave from the fields to the port were disturbed for few months until the roads were fixed.

Abyr traveled to Mexico to assess the situation. Upon her return she called for a meeting with the Kachab family and reported the following:

“I am sorry to inform you that there will be no agave for a while. The authorities estimated that it will be few months before they can fix the roads. I managed to secure a couple of shipments of agave from a friend of mine at the same old price, but it will not be enough to meet our needs for the coming quarter. At most he will be able to provide us with AED 4,350,000 worth of raw agave (direct imported material) for the first quarter of 2018 which is about 50% of our needs, according to Mahmoud’s forecast.Given the good relationship we have with our suppliers and the contracts we already we have signed with them, they assured me that there will be no increase of prices of raw agave.”

The family was devastated after hearing the news. Bilal recomposed himself and turned to Mahmoud and said: “Ok, mycousin: this is your chance to shine. Walk us through the forecasts you always prepare and show us the impact this is going to have on our operations” Mahmoud quickly projected on the screen the following table:

| Profit estimate for the first quarter of 2018 | ||

| AED | ||

| Forecasted sales | 16,800,000.0 | |

| minus COGS | 13,721,190.0 | |

| Gross margin | 3,078,810.0 | |

| Admin expenses* | 610,000.0 | |

| Shipping expenses** | 532,122.0 | |

| Sales commission (3% of sales) | 504,000.0 | |

| Financial expenses*** | 44,000.0 | 1,690,122.0 |

| Budgeted net profit | 1,388,688.0 | |

Mahmoud pointed out that in his budget he made the following assumptions/relationships:

- *ADM expenses are fixed and were increased in 2018 to include promotions & salary increases

- **Shipping costs are mixed, and the total magnitude is a function of the number of units shipped

- ***Financial expenses are expected to remain the same. No change in the outstanding debt.

- Costs of labor and overhead were adjusted to include any rates and/or prices increases expected to take place in 2018.

Mahmoud assumed the sales mix of sales dirhams of 2017 is going to apply in 2018.No changes in cost of raw agave or selling prices of the syrups are expected in the 1st quarter of 2018.

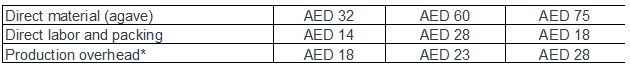

Mahmoud then presented the following production & cost schedule:

| Production Schedule and Cost Structure per Product | ||||

| Amounts in AED | AG | AGL | AGSL | |

| Direct material (agave) | 32 | 60 | 75 | |

| Direct labor and packing | 14 | 28 | 18 | |

| Production overhead* | 18 | 23 | 28 | |

* Mahmoud has combined both fixed and variable expenses in production overhead. Mahmoud estimated a fixed overhead productions costs of AED 623,070 for the first quarter of 2018. This figure was based on the fixed overheard production costs of the last quarter of 2017 adjustedfor inflation and other specific variables. He has then allocated thefixed overhead production costs equally among the number of units expected to be produced &soldof all products.

The company maintains minimum levels of all types of inventory.

Additional processing time & any additional material/agent used for different products are reflected in the variable overhead costs.

As the meeting continued, Mahmoud commented that given that the operation the Kachab family run was very lean there would be no place to cut costs. Direct material, packaging, and direct labor would remain the same at least in the short run. Similarly, production overhead will not change; the variable portion will be incurred as production continues, and the fixed portion of overheads is already very optimized.

After a moment of silence, Mahmoud said: “Perhaps we could cut our sales commission”. Bilal quickly objected and said: “No. We cannot touch the sales incentive. In these moments of crisis, we need it more. This will keep us motivated and in the right direction not to make a rush decision, like deciding to cut prices. We must continue focusing on the top line.”

Mahmoud agreed with Bilal, however he suggested they may need to come up with a limit of sales on each product if they were to keep all customers intact.

Abyr then interjected and reminded the family that the raw agave orders she had secured were not enough to produce all three products simultaneously at the proposed quantities. She then also reminded them that since their three products were being purchased by very different segmented clients, cutting one of them out of supply could mean a permanent loss of a group of clients. She proposed that all BDB clients should bear the shortage of the amount of agave-based syrup being supplied to them. Therefore, she proposed that at least 20,000 units should be produced for each of the three products.

Mahmoud agreed with Abyr’s proposal and reminded the family that this decision will come with an opportunity cost. The meeting concluded with Mahmoud taking the task of reworking the forecasts based on these new constraints and determining the opportunity cost of Abyr’sproposal.

Your task

Assume the role of Mahmoud as the Business graduate expert in managerial accounting and be prepared to discuss your findings with the BDB shareholders.Answer the following questions:

- Calculate the break-even point for the first quarter of 2018 assuming that there is no problem with the supply of raw agave and things will go as expected in the budget. Calculate the breakeven point again assuming the shortage of supply. Assume the limited available raw agave will be distributed as Abyr suggested. Do you expect the breakeven point to change? Why? Show you computations.

- Based on the given constraints (limited supply of raw agave), prepare a revised production schedule that maximizes profit for BDB. Ensure you prepare a contribution margin format income statement that supports your recommended production schedule.

- Since BDB members decided that every product of the three products BDB sells will have a minimum production of 20,000 units, is there any opportunity cost for BDB? In other words, how much profit is BDB foregoing, if any, with the decision of serving all three group of customers in the way Abyr suggested?

- In the following quarter, assuming the supply will be abundant, and production may be increased to compensate for the loss of the 1st quarter, how much sales BDB needs to make to achieve a target profit of 1, 680,000 AED. Assume the sales mix of last year.

KEY WORDS:

Cost behavior & classification, CVP & breakeven point analysis, Cost of goods manufactured (CGM), CM format of income statement, differential analysis & constraints, opportunity cost.